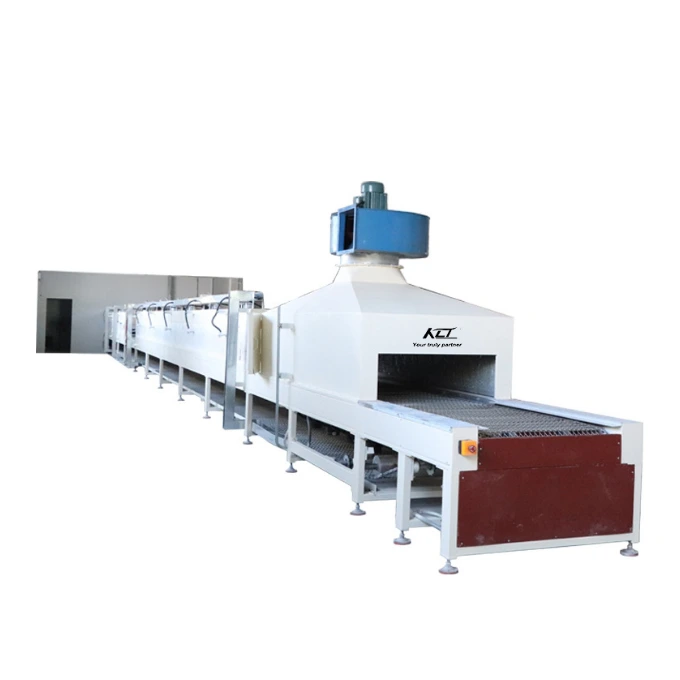

Non stick paint production line

Equipment introduction

During the design, we have made the optimal selection in combination with the actual situation of your company in an all-round way to reduce the production cost. The efficient operation of the equipment ensures that your company saves energy and improves the production efficiency in the actual production process.

Product Application

Process flow

|

NO. |

Work sequence name |

handling |

The process temperature |

Process time |

note |

|

A:Inner coating production line |

|||||

|

1 |

Put the product |

artificial |

The normal temperature |

—— |

|

|

2 |

Dust removal |

automatic |

The normal temperature |

—— |

|

|

3 |

preheating |

Natural gas |

45~85℃ |

3.0min |

|

|

4 |

Spray primer |

automatic |

The normal temperature |

—— |

|

|

5 |

Primer to dry |

Natural gas |

120~200℃ |

5.0min |

|

|

6 |

Primer cooling |

High pressure centrifugal fan |

The normal temperature |

3.0min |

|

|

7 |

Spray medium layer paint |

automatic |

The normal temperature |

—— |

|

|

8 |

Spray surface paint |

automatic |

The normal temperature |

—— |

|

|

9 |

Artifact transfer |

artificial |

The normal temperature |

—— |

|

|

10 |

Preheating stage zone |

Natural gas |

RT~80℃ |

5.0min |

|

|

11 |

Low temperature volatilization zone |

Natural gas |

80~150℃ |

10.0min |

|

|

12 |

High temperature curing zone |

Natural gas |

430℃ |

15.0min |

|

|

13 |

High temperature furnace cooling |

automatic |

The normal temperature |

6.0min |

|

|

14 |

Remove the product |

artificial |

The normal temperature |

—— |

|

|

B:Outer coating production line |

|||||

|

1 |

Put the product |

artificial |

The normal temperature |

—— |

|

|

2 |

preheating |

Natural gas/electricity |

45~55℃ |

3.0min |

|

|

3 |

Spray primer |

automatic |

The normal temperature |

—— |

|

|

4 |

Spray surface paint |

automatic |

The normal temperature |

—— |

|

|

5 |

Artifact transfer |

artificial |

The normal temperature |

—— |

|

|

6 |

Low temperature volatilization zone |

Natural gas |

RT~150℃ |

10.0min |

|

|

7 |

High temperature curing zone |

Natural gas |

380℃ |

20.0min |

|

|

8 |

High temperature furnace cooling |

automatic |

The normal temperature |

6.0min |

|

|

9 |

Remove the product |

artificial |

The normal temperature |

—— |

|

|

C:Oil removal cleaning line |

|||||

|

1 |

Put the product |

artificial |

|

|

|

|

2 |

Oil removal in advance |

Electric heating |

35~50℃ |

1.0min |

|

|

3 |

Drops of water |

natural |

|

0.5min |

|

|

4 |

The main oil removal |

Electric heating |

35~50℃ |

2.0min |

|

|

5 |

Drops of water |

natural |

|

0.5min |

|

|

6 |

Water washing 1 |

spray |

RT |

1.0min |

|

|

7 |

Drops of water |

natural |

|

0.5min |

|

|

8 |

Water washing 2 |

spray |

RT |

1.0min |

|

|

9 |

Drops of water |

natural |

|

0.5min |

|

|

10 |

Water washing 3 |

spray |

RT |

1.0min |

|

|

11 |

Drops of water |

natural |

|

0.5min |

|

|

12 |

Automatic blow dry |

automatic |

RT |

0.4min |

|

|

13 |

Moisture drying |

Natural gas heating |

150-200℃ |

6.5min |

|

|

14 |

cooling |

cooling |

RT |

4.0min |

|

|

15 |

Remove the product |

artificial |

|

|

|

Note: The above process shall be provided by Party A, and the customer's actual process shall prevail.

More details

No. 15, Yanqiao Road, Yanqiao Street, Huishan District, Wuxi City, Jiangsu Province, China